Blog

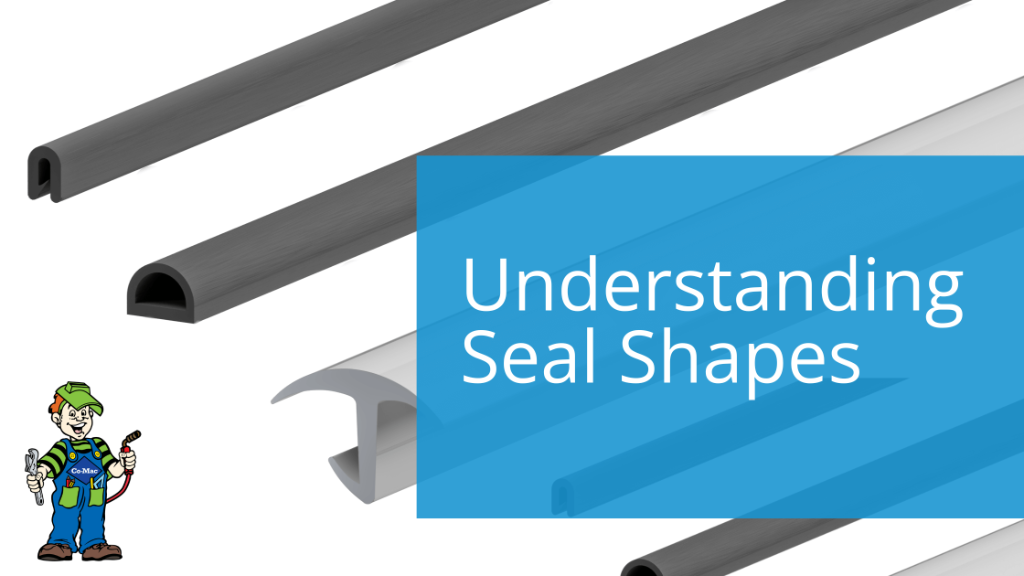

Understanding Different Shapes of Seals: A Comprehensive Guide

Seals play a crucial role in various applications, from preventing leaks to reducing vibrations and noise. They come in various materials and shapes, each designed for specific uses and conditions. In this blog, we will delve into the different shapes of seals, focusing on sponge rubber and rubber seals with profiles like D, O, U, and rectangle or flat. Additionally, we'll explore rubber and PVC shapes, such as J and H, and explain how to identify and check existing seals.

Seals play a crucial role in various applications, from preventing leaks to reducing vibrations and noise. They come in various materials and shapes, each designed for specific uses and conditions. In this blog, we will delve into the different shapes of seals, focusing on sponge rubber and rubber seals with profiles like D, O, U, and rectangle or flat. Additionally, we'll explore rubber and PVC shapes, such as J and H, and explain how to identify and check existing seals.What Does the Shape Refer To?

When we talk about the shape of a seal, we are referring to its end profile. Imagine cutting through the seal and looking at its cross-section; this is what defines its shape. The profile of a seal determines its sealing properties and suitability for different applications.

Common Shapes of Seals

D-Shaped Seals

D-shaped seals are commonly used for their excellent sealing capabilities and flexibility. The flat side of the "D" sits against the surface, providing a secure seal, while the curved side compresses to form a tight barrier. These seals are ideal for doors, hatches, and enclosures where a reliable seal against air, water, and dust is required.The D Profile can either be solid or hollow.

O-Shaped Seals

O-shaped seals are round and available both solid and hollow profiles. They are very versatile as they create a tight seal under pressure.

U-Shaped Seals

U-shaped seals have a U-shaped cross-section. They provide a double lip for better sealing. They are used in hydraulic and pneumatic systems to stop fluid leaks. These can also be used to cover over sharp edges to prevent cuts or damage.

Rectangle or Flat Seals

These seals have a rectangular or flat profile, making them ideal for sealing flat surfaces. They are often used in applications where a gasket-like seal is needed, such as in machinery, automotive parts, and industrial equipment.

Truck or Container Door Rubber and PVC Seal Shapes

H Seal and J Seal are commonly used to seal truck body and container doors.

J-Shaped Seals

J-shaped seals have a hook-like profile. The J-shape makes them easy to install and provides a good seal. The PVC J seal has a hard PVC Right angle to butt into and fasten to the side of the door, with a flexible seal to seal the door. Also available is a rubber J seal, which is entirely made of rubber.

H-Shaped PVC Seals

H-shaped seals are made from Hard PVC with a flexible seal. They have an H-shaped cross-section which is designed to fit the door width precisely, creating a snug fit.

How to Check Existing Seals

It's important to check seals to make sure they work well. Here’s how to check them:

- Inspect the Seal’s Condition: Look for cracks, splits, or deformation. Replace worn-out seals.

- Check the Fit: Ensure the seal fits snugly. A loose or tight seal may not work well.

- Test for Leaks: Apply pressure or use water to see if the seal holds. Replace if it leaks.

- Compare with New Seals: Compare the old seal with a new one. Differences may indicate degradation.

Conclusion

Understanding the different shapes of seals and their applications is essential for selecting the right seal for your needs. Whether it's a D, O, U, rectangle, J, or H-shaped seal, each has unique properties that make it suitable for specific uses. Regularly checking and maintaining your seals ensures optimal performance and longevity, keeping your systems running smoothly and efficiently.

By recognizing the shape and profile of your seals, you can ensure you choose the best one for the job, providing reliable protection and sealing for your applications.

Need some help identifying a trim or seal that you need? Send a photo of the end profile to ask@comac.co.nz

Latest Blogs

How to Build Security Sliding Doors for a Outdoor Sports Court? Outdoor Security Sliding Door Project Review. 5931 Beam Clamp Load Testing - Vertical Pull Test | Co-Mac Types of Gate Rollers for U Track: Which One is Right for You? Choosing the Right Hinge for Your Chiller: Rising vs. Non-Rising Hinges Understanding Different Shapes of Seals: A Comprehensive Guide Accelerated Salt Spray Testing of Rust Protection Zinc Paints Top 3 Lock Options for Sliding Doors and Gates Container Door Hardware: A Guide to Container Hinges, Locks and Seals Top Tips for Choosing Durable Sliding Door Hardware in New Zealand's Climate: Your Ultimate Guide Self Closing Gate Hardware In the Community: Picking Daffodils 3 Types of Drop T Latches 2022 Catalogue Coming Soon! How long will Linear Slides last? We tested them past 80,000 cycles - find out how they performed How Long Will a Gas Strut Last? Engineering Forces Explained: Tensile, Compressive, Shear and Torsion Co-Mac Boredom Busters - How We Did It Co-Mac Boredom Busters Is a Double Nut Better than a Single Nut? How much Better?

.jpg)