Blog

Accelerated Salt Spray Testing of Rust Protection Zinc Paints

Using our Salt Spray Testing Machine we tested different kinds of Rust Protection Zinc Paints made by CRC and Chem-Z.

The samples are as follows:

Sample 1 (Left): Chem Z Zinc Protection 99% Pure, the average Paint cover is 81.5 micron.

Sample 2 (Right): CRC Zinc Bright, the average paint cover is 49.7 micron

Sample 3 (Left): Chem Z Zinc Silver, The average paint cover is 50.2 micron

Sample 4 (Right): CRC Zinc IT, the average paint cover is 43.2 micron.

Sample 5: This sample had no paint coating at all, it was left as plain mild steel for comparison purposes.

Testing:

The samples were placed into the Salt Spray Testing Machine, which simulates an environment with high salt concentrations, eg; coastal or marine environments. This is achieved by atomising a 6% salt solution into the air and constantly covering the items placed inside the tank for the duration of the test, this greatly increases the exposure to salt.

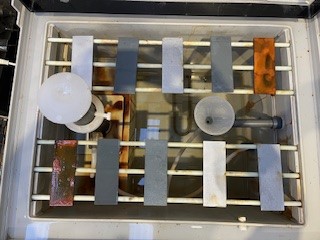

These pictures show the progression of the test over the following few days:

Day 1 – Start of the test. Day 1 - After 8.5 hours total test time

Day 2 - 17 hours total test time Day 3 - 25.75 hours total test time

Day 5 - 34.75 hours total test time Results

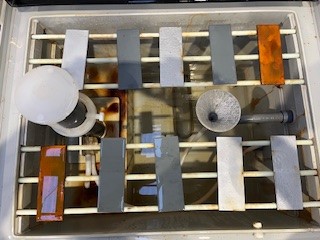

In total the test ran across 8 days with a total time of 60.25 hours. After the completion of the test there was some obvious differences between each type of paint. They were all somewhat effective, but there was one that stood out as the best preforming under our test conditions. These images show the results of each type at the end of the test:

Sample 1: Started out pretty good but started blistering after a few days in the tank and then started getting some small rust spots by the sixth day which grew until the end of the test.

Sample 2: Spots of rust started growing after only three days (one of which the tank wasn’t running due to being a public holiday). The rust got steadily worse throughout the rest of the testing period.

Sample 3: Spots of rust started growing after three days and grew steadily for the rest of the test period.

Sample 4: By far the best performing paint, a very small amount of surface rust around the edges of the steel plate.

Sample 5: As expected, this one is the worst due to being bare steel with no protection at all. It rusted very quickly all over.

Conclusion

Using protective paints can help protect plain steel against rust. In this accelerated test all 4 options were somewhat effective at preventing rust from forming and spreading.

Latest Blogs

How to Build Security Sliding Doors for a Outdoor Sports Court? Outdoor Security Sliding Door Project Review. 5931 Beam Clamp Load Testing - Vertical Pull Test | Co-Mac Types of Gate Rollers for U Track: Which One is Right for You? Choosing the Right Hinge for Your Chiller: Rising vs. Non-Rising Hinges Understanding Different Shapes of Seals: A Comprehensive Guide Accelerated Salt Spray Testing of Rust Protection Zinc Paints Top 3 Lock Options for Sliding Doors and Gates Container Door Hardware: A Guide to Container Hinges, Locks and Seals Top Tips for Choosing Durable Sliding Door Hardware in New Zealand's Climate: Your Ultimate Guide Self Closing Gate Hardware In the Community: Picking Daffodils 3 Types of Drop T Latches 2022 Catalogue Coming Soon! How long will Linear Slides last? We tested them past 80,000 cycles - find out how they performed How Long Will a Gas Strut Last? Engineering Forces Explained: Tensile, Compressive, Shear and Torsion Co-Mac Boredom Busters - How We Did It Co-Mac Boredom Busters Is a Double Nut Better than a Single Nut? How much Better?